100% Original Factory Electric Steam Boilers - Boiler Water Treatment – Double Rings

100% Original Factory Electric Steam Boilers - Boiler Water Treatment – Double Rings Detail:

More photos

1. Quartz sand filter — mainly used for the removal of sediment from water.

2. Active Carbon filter– mainly used for chlorine removal and other organic gases and to clear up the taste of water .

3. Water Softener– exchange “ions” of calcium and magnesium with the most common and easiest method.

4. Precision filter– mainly used for removing microorganisms,chlorine,part of the heavy metal ions more precisely

5. High pressure pump– Provide the high pressure to RO membrane ro.

6. RO system– main part of the plant. The RO membrane’s desalting rate can reach 99%, removing over 99% ions.

RO membranes combine auto wash and manual wash together which can protect RO membrane easily.

7. Ozone generator – Kills 99.9 percent of known harmful bacteria.

Product detail pictures:

Related Product Guide:

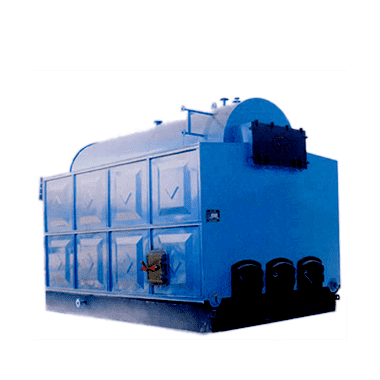

Boiler Structure

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for 100% Original Factory Electric Steam Boilers - Boiler Water Treatment – Double Rings , The product will supply to all over the world, such as: Yemen, Iran, Nepal, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!