18 Years Factory Oil Fired Combi Boiler - Biomass Hot Water Boiler – Double Rings

18 Years Factory Oil Fired Combi Boiler - Biomass Hot Water Boiler – Double Rings Detail:

Introduction :

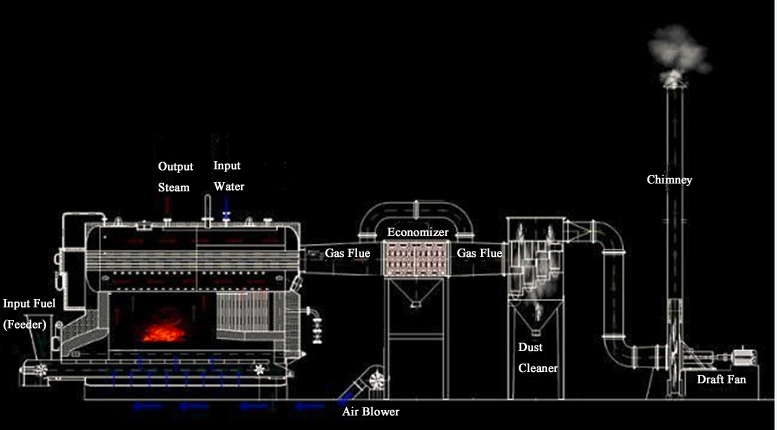

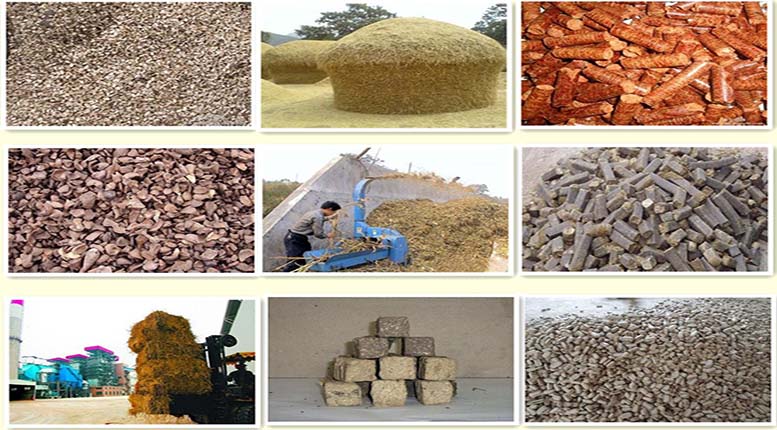

Biomass boiler is horizontal three-back water fire pipe composite boiler. The fuel can be Biomass,coal,wood,rice husk,shells,pellets,bagasse,waste etc..

Display

Feature:

1. High thermal efficiency

2. By mechanize operation, reduce intensity of labour of stoker.

3. Easy for installation, when on site, only install slag remover, valve, pipe, water and power, etc., the boiler can be launched into running, additionally, the firing is fast.

4. Easy for installation and moving, save a great amount of capital outlay.

5. Fule: Biomass, coal, wood, rice husk, shells, pellets, bagasse, waste , lower calorific value: 12792KJ/Kg.

Parameter :

DZG(L)Bearing Pressure Hot water boiler

Main Technology Parameter List

| Model | DZG0.7-0.7/95/70 DZL0.7-0.7/95/70 |

DZG1.4-0.7/95/70 DZL1.4-0.7/95/70 DZL1.4-1.0/115/70 |

DZL28-1.0/115/70 DZL2.8-1.25/130/70 |

DZL4.2-1.0/115/70 DZL4.2-1.25/130/70 |

|

| Rated Capacity T/h | 0.7 | 1.4 | 2.8 | 4.2 | |

| Rated Working Pressure Mpa | 0.7 | 0.7/1.0 | 1.0/1.25 | 1.0/1.25 | |

| Rated Steam Temp. ℃ | 95 | 95/115 | 115/130 | 115/130 | |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | |

| Fuel Consumption Kg/H | ~150 | ~310 | ~590 | ~900 | |

| Thermal Efficiency % | 75 | 78 | 79 | 77.44 | |

| Heating Surface | Boiler Body m² | 32.4 | 33.85 | 75.75 | 142 |

| Economizer m² | 24.64 | 38.5 | 87.2 | ||

| Grate area m² | 1.4/2.05 | 2.3/3.5 | 4.66 | 7.4 | |

| Designed Fuel Type | Biomass | Biomass | Biomass | Biomass | |

| Max. Transport Weight T | ~16 | ~21 | ~26.5 | ~30 | |

| Max. Transport Dimension m | 4.3×2.25×2.955.26×2.25×2.95 | 5.1×2.2×3.35.9×2.2×3.3 | 6.5×2.6×3.5 | 6.01×3.4×3.57.29×2.9×1.7 | |

| Model | DZL7-1.0/115/70 | DZL14-1.0/115/70 | DZL29-1.25/130/70 | DZL46-1.25/130/70 | DZL58-1.25/130/70 | DZL70-1.25/130/70 |

| Rated Capacity T/h | 7 | 14 | 29 | 46 | 58 | 70 |

| Rated Working Pressure Mpa | 1.0 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| Rated Steam Temp. ℃ | 115 | 115 | 130 | 130 | 130 | 130 |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | 70 | 70 |

| Heating AreaBoiler Body m² | 228.6 | 434.7 | Radiation:73.07Convection:903.01 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 |

| Grate area m² | 11.5 | 22.5 | 34.5 | 57.8 | 77 | 91 |

| Fuel Consumption Kg/h | ~1440 | ~2700 | ~6610 | ~10500 | ~12800 | ~15300 |

| Thermal Efficiency % | 80 | 80 | 82.5 | 82.05 | 83.03 | 83.28 |

| Max. Transport Weight Ton | 35 | 28 | 19.68 | 28.796 | 31 | 31 |

Note: Parameter is just for reference, the exact parameter should follow the factory technical data.

Product detail pictures:

Related Product Guide:

Boiler Structure

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for 18 Years Factory Oil Fired Combi Boiler - Biomass Hot Water Boiler – Double Rings , The product will supply to all over the world, such as: kazan, Mauritius, Belgium, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.