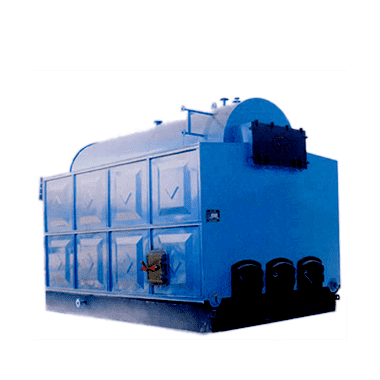

China 2 Mw Biomass Boiler - Vertical Wood /Coal Boiler – Double Rings

China 2 Mw Biomass Boiler - Vertical Wood /Coal Boiler – Double Rings Detail:

Introduction :

Vertical type boiler, adopt water&fire tube structure, suitable for coal/wood/solid material fire.

Vertical boiler, thermal capacity in 100kw/200kw/300kw/350kw/500kw/600kw/700kw/1000kw per hour.

Feature:

* Compact, small footprint, easy installation.

* Fully furnished heating surface, flue gas temperature is low.

* Using the world famous original burner, implement automatic and efficient combustion, the combustion efficiency.

* Microcomputer automatic control, super-pressure automatic protection, low water level automatic protection and automatic replenishment.

* Extra-thick insulation layer design, effective insulation, furnace surface testimonies low heat loss.

* The concentration of dust emission is small, fully meet the state requirements for a class of environmental protection areas.

Parameter :

Main Specification :

|

Model |

LSC0.3-0.7-AⅡ |

LSC0.5-0.7-AⅡ |

LSC0.7-0.7-AⅡ |

LSC0.95-0.8-AⅡ |

|||||

|

Steam Capacity t/h

|

0.3

|

0.5

|

0.7

|

0.95 |

|||||

|

Steam Pressure MPa |

0.7

|

0.8

|

|||||||

|

Temperature ℃ |

170.4 |

175.35 |

|||||||

|

Running Range in the safety % |

80-100 |

||||||||

| Fuel |

Bituminous Coal |

||||||||

| Fuel Consumption Kg/h |

56.1 |

92.8 |

129.1 |

177.2 |

|||||

|

Efficiency % |

78 |

78.8 |

79.45 |

78.7 |

|||||

|

Exhaust Gas Temperature ℃ |

201.7 |

203.8 |

193.3 |

200.2 |

|||||

|

Exhaust Gas Ratio |

1.5 |

1.4 |

1.35 |

1.45 |

|||||

|

Feed Water Temperature℃ |

20 |

||||||||

|

Boiler Body Cost Weight |

1.847 |

2.876 |

3.431 |

4.876 |

|||||

| Steel Frame Weight |

1.3 |

1.57 |

1.71 |

1.9 |

|||||

|

Chain Weight |

76 |

110 |

127 |

260 |

|||||

|

Power KW |

3 |

3 |

3 |

3 |

|||||

|

Water Quality |

Water Hardness:≤0.03 Oxygen Capacity:≤0.1mg/L |

||||||||

|

|

Boiler water alkalinity 10.0-12.0PH(25℃) |

||||||||

|

Blowdown Rate % |

2 |

||||||||

| Boiler design, manufacture, operation main implementation criteria: | |||||||||

| 1、”Steam Boiler Safety Technology Supervision” 96 edition | |||||||||

| 2、”Supervision and management regulations for energy saving technologies” TSGG0002-2010 | |||||||||

| 3、GB/T16508-1996 “Shell boiler pressure parts strength calculation” | |||||||||

| 4、”Laminar burning industrial boilers burning and boiling thermal calculation method” | |||||||||

| 5、”Boiler equipment aerodynamic calculation standard method” | |||||||||

| 6、”Boiler installation construction and acceptance norms” GB50273-2009 | |||||||||

| 7、”Industrial Boiler Water Quality “GB/T1576-2008 | |||||||||

Product detail pictures:

Related Product Guide:

Boiler Structure

"Based on domestic market and expand abroad business" is our progress strategy for China 2 Mw Biomass Boiler - Vertical Wood /Coal Boiler – Double Rings , The product will supply to all over the world, such as: Lithuania, Philippines, Japan, Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!