China Best Oil Fired Boilers Manufacturer - LPG Pressure Tank – Double Rings

China Best Oil Fired Boilers Manufacturer - LPG Pressure Tank – Double Rings Detail:

Introduction:

Pressure vessel equipment plays an important role in the petrochemical industry, the energy industry, scientific research and military sectors etc.

Pressure vessel container body consist of cylinder, sealing head, flange, sealing elements, open pore and connected pipe, bearing.

In addition, also equipped with safety devices, meter and safety internals for protection purpose .

Pressure Vessel Main Performance Parameter List

Steam Pressure1.0Mpa

Inlet Temperature 250℃

Saturation Temperature 179℃

Heating Water:Inlet Temperature 90℃;

Outlet Temperature 140℃

Product detail pictures:

Related Product Guide:

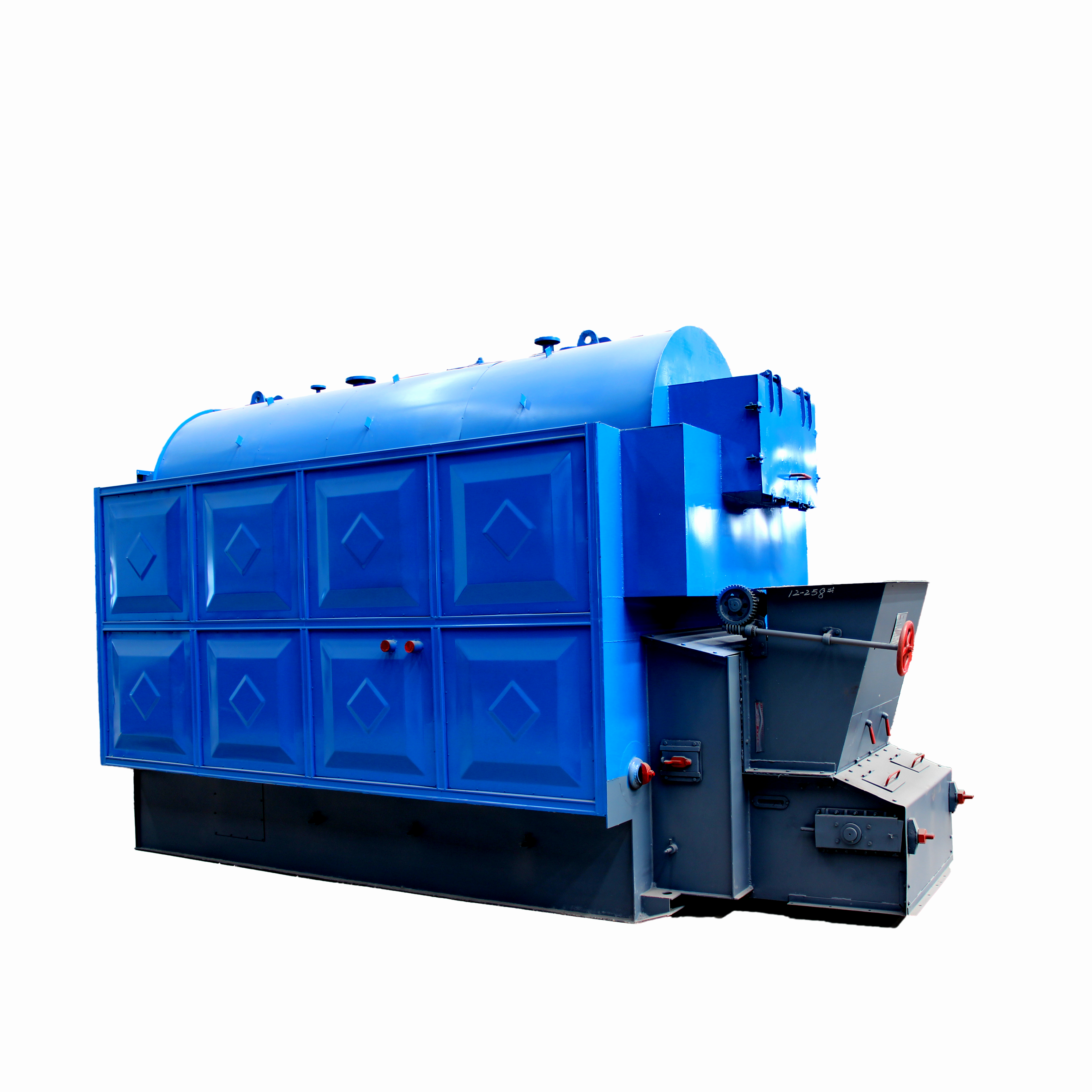

Boiler Structure

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for China Best Oil Fired Boilers Manufacturer - LPG Pressure Tank – Double Rings , The product will supply to all over the world, such as: United Arab emirates, Jordan, US, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

Write your message here and send it to us