China Boiler Electrical Factories - Pellets Shells Husk Biomass Boiler – Double Rings

China Boiler Electrical Factories - Pellets Shells Husk Biomass Boiler – Double Rings Detail:

Parameter :

DZG(L)Horizontal Type Biomass-Burning Steam Boiler

Main Technology Parameter List

| Model | DZG2-1.0-S DZL2-1.25-S DZL2-1.57-S DZL2-2.45-S |

DZG4-1.25-S DZL4-1.25-S DZL4-1.57-S DZL4-2.45-S |

DZL6-1.25-S DZL6-1.57-S DZL6-2.45-S |

DZL8-1.25-S DZL8-1.57-S DZL8-2.45-S |

DZL10-1.25-S DZL10-1.57-S DZL10-2.45-S |

|||||||

| Rated Capacity T/h | 2 | 4 | 6 | 8 | 10 | |||||||

| Rated Working Pressure Mpa | 1.0/1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | |||||||

| Rated Steam Temp. ℃ | 183/194/204/226 | 194/204/226 | 194/204/226 | 203.04 | 194/204/226 | |||||||

| Feed Water Temp. ℃ | 20 | 20 | 20/60 | 20 | 20/60 | |||||||

| Fuel Consumption Kg/H | ~310 | ~590 | ~900 | ~1200 | ~1440 | |||||||

| Thermal Efficiency % | 78 | 80 | 77.44 | 78 | 80.6 | |||||||

| Heating Surface m² | Boiler Body | 33.85 | 75.75 | 142 | 205 | 347 | ||||||

| Economizer | 24.64 | 38.5 | 87.2 | 139.52 | ||||||||

| Grate area m² | 3.5 | 4.66 | 7.4 | 8.4 | 10.98 | |||||||

| Designed Fuel Type | Biomass | Biomass | Biomass | Biomass | Biomass | |||||||

| Max.Transport Weight Ton | 21 | 26.5 | 38 | 33 | 28/29 | |||||||

| Max. Transport Dimension m | 5.9×2.2×3.3 | 6.5×2.6×3.524 | 7.4×3.2×4.2 | 8.1×3.2×4.2 | 7.6×3.2×3.5 | |||||||

| Boiler Auxiliary Equipment Model and Specification | ||||||||||||

| Air Blower | Model | T4-72-11;3.2A;Right315° | T4-72-11;4A;Righ 315° | T4-72-11;5A; Right 225° | GG8-Na;7.1A; Right 225° | 10TG811DRight 225° | ||||||

| Motor Power | N=3 Kw | N=5.5 Kw | N=11 Kw | N=11 Kw | N=15 Kw | |||||||

| Draft Fan | Model | Y9-26;6.3C; Right 0° | Y-9-26;9D; Right 0° | Y-8-39;9D;Right 0° | GY8-1;Na9.5D;Right 0° | 10JY;9.5D; Right 0° | ||||||

| Motor Power | N=11 Kw | N=22 Kw | N=30Kw | N=37Kw | N=45 Kw | |||||||

| Gear Box | Model | GL-5P | GL-5P | GL-10P | GL-16P | |||||||

| Motor Power | N=0.55 Kw | N=0.55 Kw | N=1.1 Kw | N=1.1 Kw | ||||||||

| Feed Water Pump | Model | 1½ GC 5×7 | 1½ GC 5×7 | DG 6-25×7 | 2GC-5xT | 1½ GC 6×6 | ||||||

| Motor Power | N=7.5 Kw | N=7.5 Kw | N=7.5 Kw | N=22 Kw | N=2.2 Kw | |||||||

| Dust Remover | Model | XD-2 | XD-4 | XD-6 | XD-8 | XD-10 | ||||||

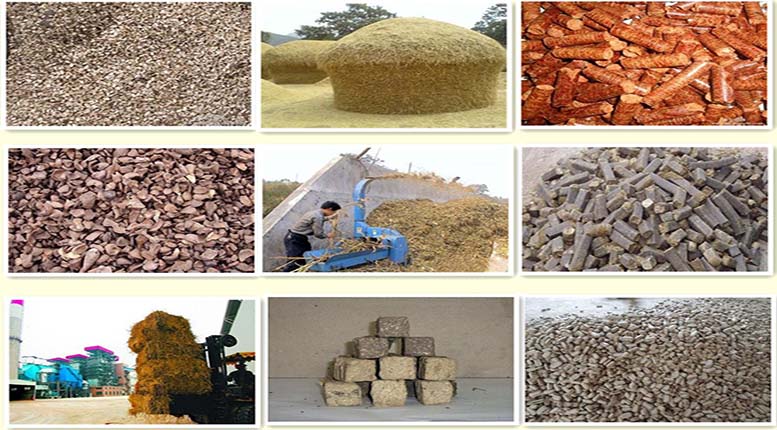

Fuel: Wood,Rice Husk,shells,Pellets,bagasse,waste etc..

Display

Flow Chat

Product detail pictures:

Related Product Guide:

Boiler Structure

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for China Boiler Electrical Factories - Pellets Shells Husk Biomass Boiler – Double Rings , The product will supply to all over the world, such as: Boston, Iran, Latvia, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

Write your message here and send it to us