China Coal Boiler Manufacturers - Biomass Steam Boiler – Double Rings

China Coal Boiler Manufacturers - Biomass Steam Boiler – Double Rings Detail:

Biomass Boiler-Hot Sale- Easy Installation Low Heating Value Fuel Wood Rice Husk Pellets etc.

Introduction :

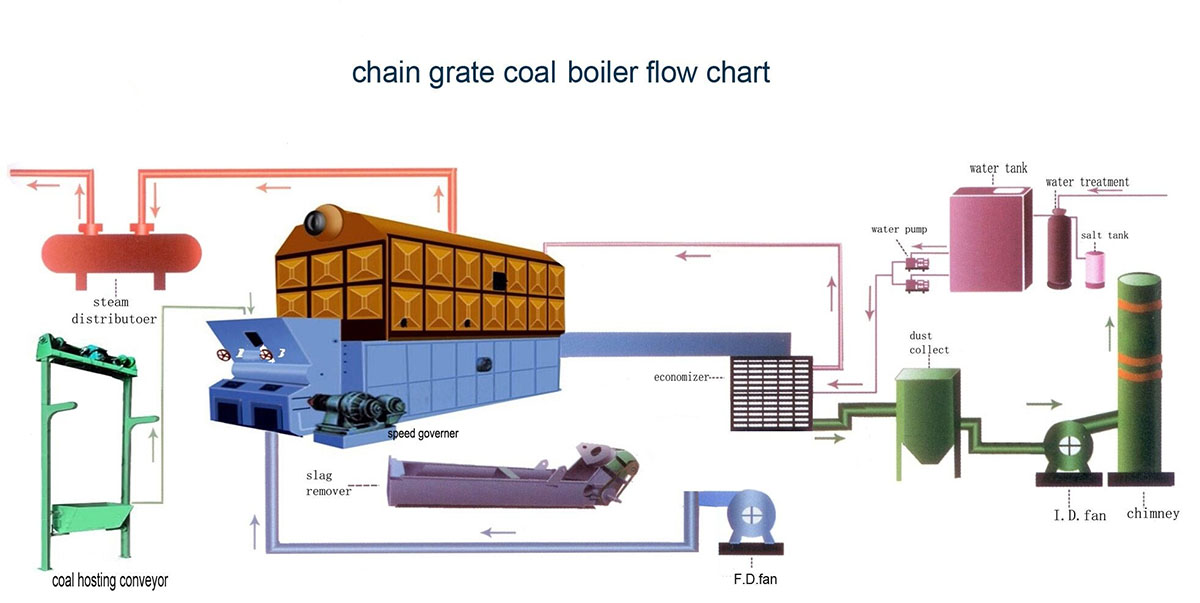

Biomass Steam Boiler is horizontal three-back water fire pipe composite boiler. Fix fire tube in drum and the light pipe water wall is fixed on the right and left sides of the furnace. With light chain grate stoker for mechanical feeding and by the draft fan and blower for mechanical ventilation, realize mechanical taphole by scraper slag remover.

The hopper of fuel drops to grate bar, then enter furnace for burning, by the ashes room above the back arch, the flame gets through the first backhaul fire tube to front smokebox, then turn back from front smokebox to the second flue for economizer and dust collector, at last, released into the atmosphere by the draft fan through chimney.

Display

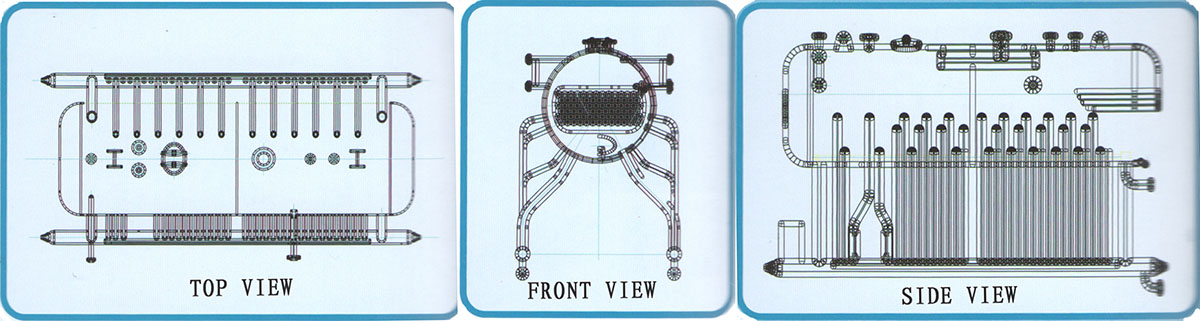

Structure

Biomass Boiler Feature:

1. High thermal efficiency

2. By mechanize operation, reduce intensity of labour of stoker.

3. Easy for installation, when on site, only install slag remover, valve, pipe, water and power, etc., the boiler can be launched into running, additionally, the firing is fast.

4. Easy for installation and moving, save a great amount of capital outlay.

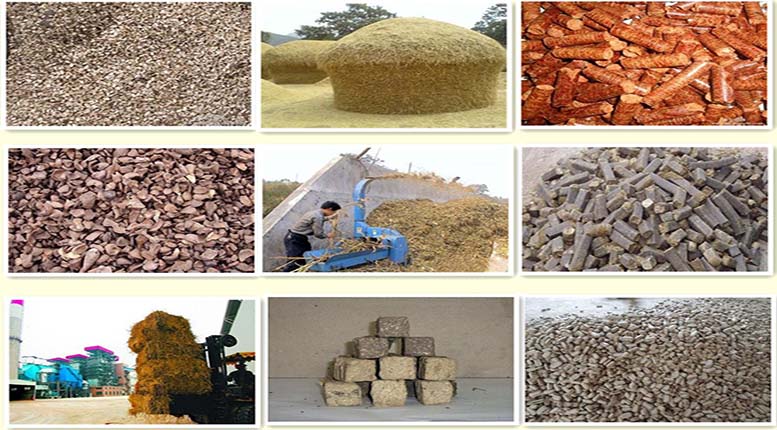

5. Fule: Biomass, coal, wood, rice husk, shells, pellets, bagasse, waste , lower calorific value: 12792KJ/Kg.

Parameter :

DZG(L)Horizontal Type Biomass-Burning Steam Boiler

Main Technology Parameter List

| Model | DZG2-1.0-S DZL2-1.25-S DZL2-1.57-S DZL2-2.45-S |

DZG4-1.25-S DZL4-1.25-S DZL4-1.57-S DZL4-2.45-S |

DZL6-1.25-S DZL6-1.57-S DZL6-2.45-S |

DZL8-1.25-S DZL8-1.57-S DZL8-2.45-S |

DZL10-1.25-S DZL10-1.57-S DZL10-2.45-S |

|

| Rated Capacity T/h | 2 | 4 | 6 | 8 | 10 | |

| Rated Working Pressure Mpa | 1.0/1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | |

| Rated Steam Temp. ℃ | 183/194/204/226 | 194/204/226 | 194/204/226 | 203.04 | 194/204/226 | |

| Feed Water Temp. ℃ | 20 | 20 | 20/60 | 20 | 20/60 | |

| Fuel Consumption Kg/H | ~310 | ~590 | ~900 | ~1200 | ~1440 | |

| Thermal Efficiency % | 78 | 80 | 77.44 | 78 | 80.6 | |

| Heating Surface m² | Boiler Body | 33.85 | 75.75 | 142 | 205 | 347 |

| Economizer | 24.64 | 38.5 | 87.2 | 139.52 | ||

| Grate area m² | 3.5 | 4.66 | 7.4 | 8.4 | 10.98 | |

| Designed Fuel | Biomass | Biomass | Biomass | Biomass | Biomass | |

| Max.Transport Weight Ton | 21 | 26.5 | 38 | 33 | 28/29 | |

| Max. Transport Dimension m | 5.9×2.2×3.3 | 6.5×2.6×3.524 | 7.4×3.2×4.2 | 8.1×3.2×4.2 | 7.6×3.2×3.5 | |

Product detail pictures:

Related Product Guide:

Boiler Structure

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for China Coal Boiler Manufacturers - Biomass Steam Boiler – Double Rings , The product will supply to all over the world, such as: St. Petersburg, Liverpool, Boston, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.