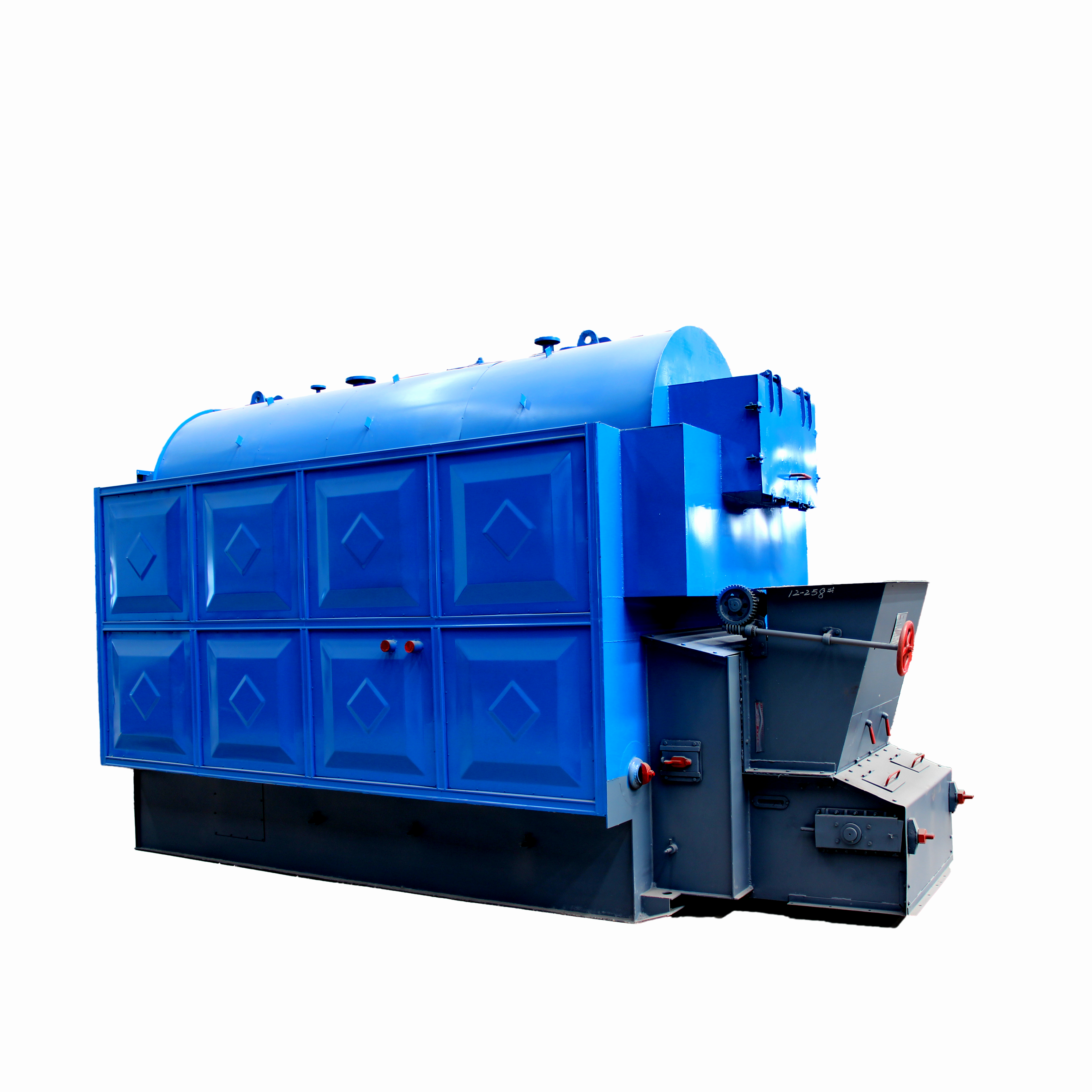

China Factory for Oil Burning Boiler - Coal Boiler Biomass Boiler Reducer – Double Rings

China Factory for Oil Burning Boiler - Coal Boiler Biomass Boiler Reducer – Double Rings Detail:

Reducer used in DR Boiler

• The main parts adopt high quality carbon structural refined steel.With high strength, high transmission efficiency and reliable operation, long service life, etc.

• Respectively using multilevel, stepless frequency conversion speed regulating mode. User can reasonably match speed reducer according to the different operation condition of boiler.With the features of easy operation, energy saving, etc

• With characteristics of large transmission torque and speed ratio, less consumed power,compact structure, and wide use.

Product detail pictures:

Related Product Guide:

Boiler Structure

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for China Factory for Oil Burning Boiler - Coal Boiler Biomass Boiler Reducer – Double Rings , The product will supply to all over the world, such as: Qatar, Jeddah, Danish, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

Write your message here and send it to us