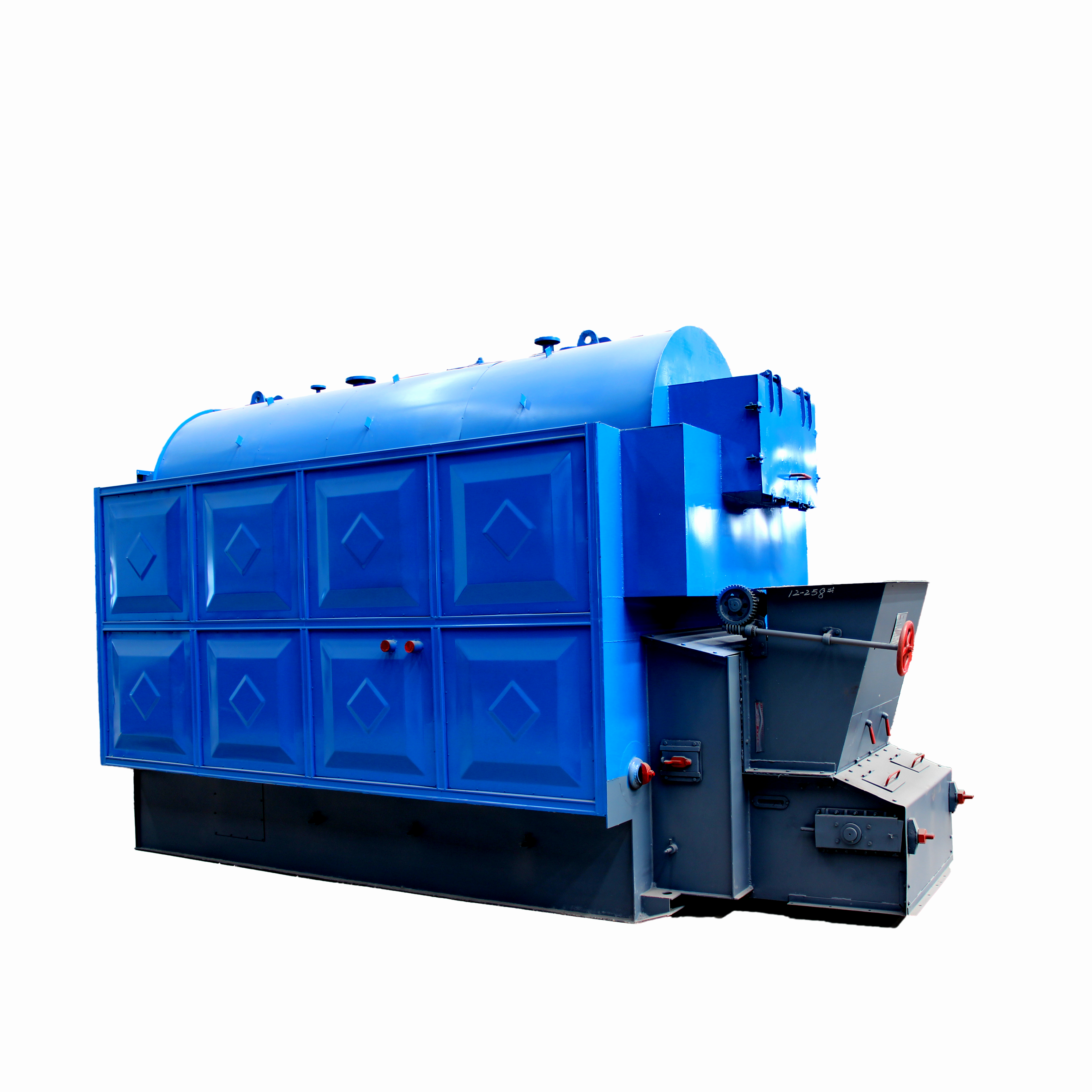

China Manufacturer for Electric Steam Generator - Coal Boiler Biomass Boiler Chimney – Double Rings

China Manufacturer for Electric Steam Generator - Coal Boiler Biomass Boiler Chimney – Double Rings Detail:

Used in Boiler

The height of a chimney affects its ability to deliver flue gas to the external environment through the chimney effect.

In addition, the diffusion of pollutants using chimneys at high altitudes can reduce the impact on the surrounding environment.

A chimney high enough to allow the chemicals in the air to partially or completely neutralize themselves before reaching the ground level, in the case of chemical erosion.

Dispersion of pollutants over a larger area reduces their concentration and promotes compliance with regulatory restrictions.

Product detail pictures:

Related Product Guide:

Boiler Structure

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Manufacturer for Electric Steam Generator - Coal Boiler Biomass Boiler Chimney – Double Rings , The product will supply to all over the world, such as: Malta, Japan, San Francisco, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.

Write your message here and send it to us