Circulating Fluidized Bed Supplier - Vertical Wood /Coal Boiler – Double Rings

Circulating Fluidized Bed Supplier - Vertical Wood /Coal Boiler – Double Rings Detail:

Introduction :

Vertical type boiler, adopt water&fire tube structure, suitable for coal/wood/solid material fire.

Vertical boiler, thermal capacity in 100kw/200kw/300kw/350kw/500kw/600kw/700kw/1000kw per hour.

Feature:

* Compact, small footprint, easy installation.

* Fully furnished heating surface, flue gas temperature is low.

* Using the world famous original burner, implement automatic and efficient combustion, the combustion efficiency.

* Microcomputer automatic control, super-pressure automatic protection, low water level automatic protection and automatic replenishment.

* Extra-thick insulation layer design, effective insulation, furnace surface testimonies low heat loss.

* The concentration of dust emission is small, fully meet the state requirements for a class of environmental protection areas.

Parameter :

Main Specification :

|

Model |

LSC0.3-0.7-AⅡ |

LSC0.5-0.7-AⅡ |

LSC0.7-0.7-AⅡ |

LSC0.95-0.8-AⅡ |

|||||

|

Steam Capacity t/h

|

0.3

|

0.5

|

0.7

|

0.95 |

|||||

|

Steam Pressure MPa |

0.7

|

0.8

|

|||||||

|

Temperature ℃ |

170.4 |

175.35 |

|||||||

|

Running Range in the safety % |

80-100 |

||||||||

| Fuel |

Bituminous Coal |

||||||||

| Fuel Consumption Kg/h |

56.1 |

92.8 |

129.1 |

177.2 |

|||||

|

Efficiency % |

78 |

78.8 |

79.45 |

78.7 |

|||||

|

Exhaust Gas Temperature ℃ |

201.7 |

203.8 |

193.3 |

200.2 |

|||||

|

Exhaust Gas Ratio |

1.5 |

1.4 |

1.35 |

1.45 |

|||||

|

Feed Water Temperature℃ |

20 |

||||||||

|

Boiler Body Cost Weight |

1.847 |

2.876 |

3.431 |

4.876 |

|||||

| Steel Frame Weight |

1.3 |

1.57 |

1.71 |

1.9 |

|||||

|

Chain Weight |

76 |

110 |

127 |

260 |

|||||

|

Power KW |

3 |

3 |

3 |

3 |

|||||

|

Water Quality |

Water Hardness:≤0.03 Oxygen Capacity:≤0.1mg/L |

||||||||

|

|

Boiler water alkalinity 10.0-12.0PH(25℃) |

||||||||

|

Blowdown Rate % |

2 |

||||||||

| Boiler design, manufacture, operation main implementation criteria: | |||||||||

| 1、”Steam Boiler Safety Technology Supervision” 96 edition | |||||||||

| 2、”Supervision and management regulations for energy saving technologies” TSGG0002-2010 | |||||||||

| 3、GB/T16508-1996 “Shell boiler pressure parts strength calculation” | |||||||||

| 4、”Laminar burning industrial boilers burning and boiling thermal calculation method” | |||||||||

| 5、”Boiler equipment aerodynamic calculation standard method” | |||||||||

| 6、”Boiler installation construction and acceptance norms” GB50273-2009 | |||||||||

| 7、”Industrial Boiler Water Quality “GB/T1576-2008 | |||||||||

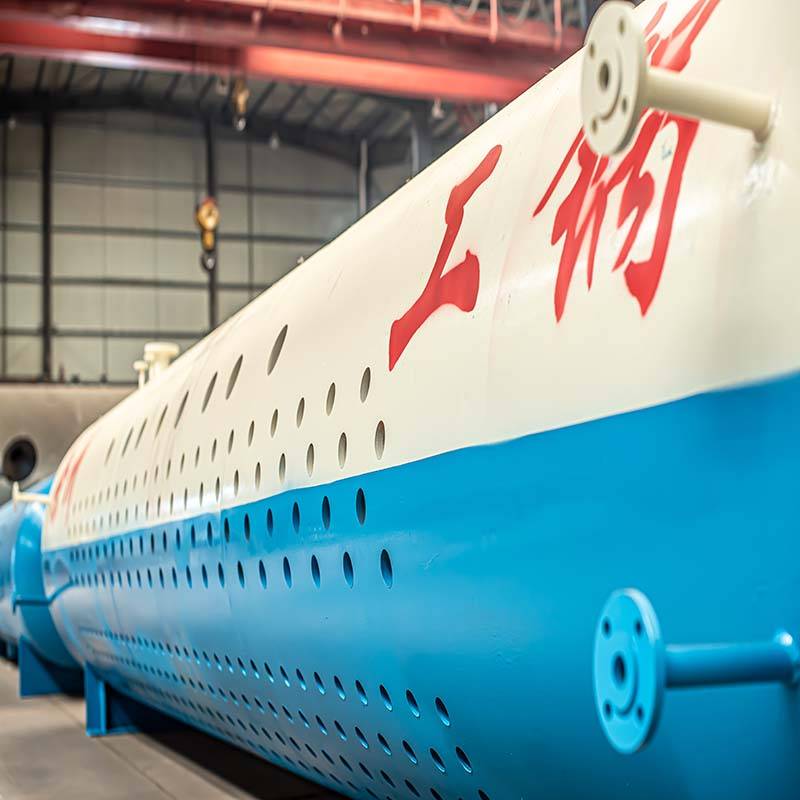

Product detail pictures:

Related Product Guide:

Boiler Structure

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for Circulating Fluidized Bed Supplier - Vertical Wood /Coal Boiler – Double Rings , The product will supply to all over the world, such as: Madagascar, Bhutan, panama, If you are interested in any of our products and solutions or would like to discuss a custom order, remember to feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!