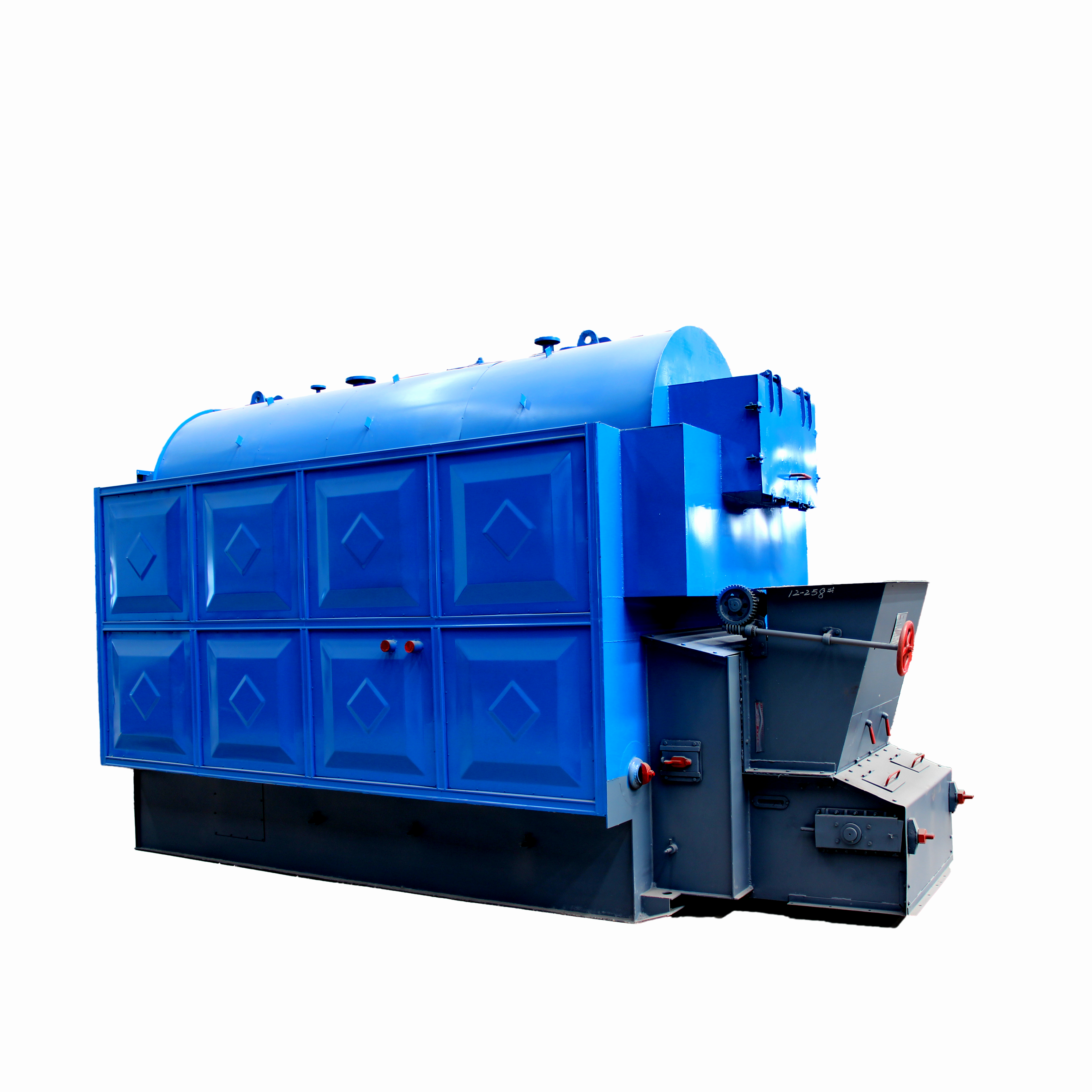

Coal Boiler Supplier - Boiler Flue – Double Rings

Coal Boiler Supplier - Boiler Flue – Double Rings Detail:

Used in Boiler

Introduction

Industrial smoke exhaust, air into the pipe, the pipe is equipped with a damper (valve) to regulate the wind speed and pressure in the pipe.

It is composed of furnace wall, partial heating surface pipe and cladding wall pipe to guide the flow of smoke, and through each heating surface for heat exchange, divided into horizontal flue and tail flue.

The main smoke duct section size of the large capacity boiler is very large, in order to bear and transfer the load, to ensure that the smoke duct parts have appropriate strength and stiffness, keep the geometry of the parts, and avoid the smoke duct parts wall plate reinforcement rib specification is too large, often need to be set in the smoke duct parts of the internal support rod.

Product detail pictures:

Related Product Guide:

Boiler Structure

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Coal Boiler Supplier - Boiler Flue – Double Rings , The product will supply to all over the world, such as: Kenya, Greece, Jordan, Nowadays our merchandise sell all over the domestic and abroad thanks for the regular and new customers support. We supply high quality product and competitive price, welcome the regular and new customers cooperate with us!

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!