Fire Tube Boiler Supplier - Coal Boiler Biomass Boiler I.D.Fan – Double Rings

Fire Tube Boiler Supplier - Coal Boiler Biomass Boiler I.D.Fan – Double Rings Detail:

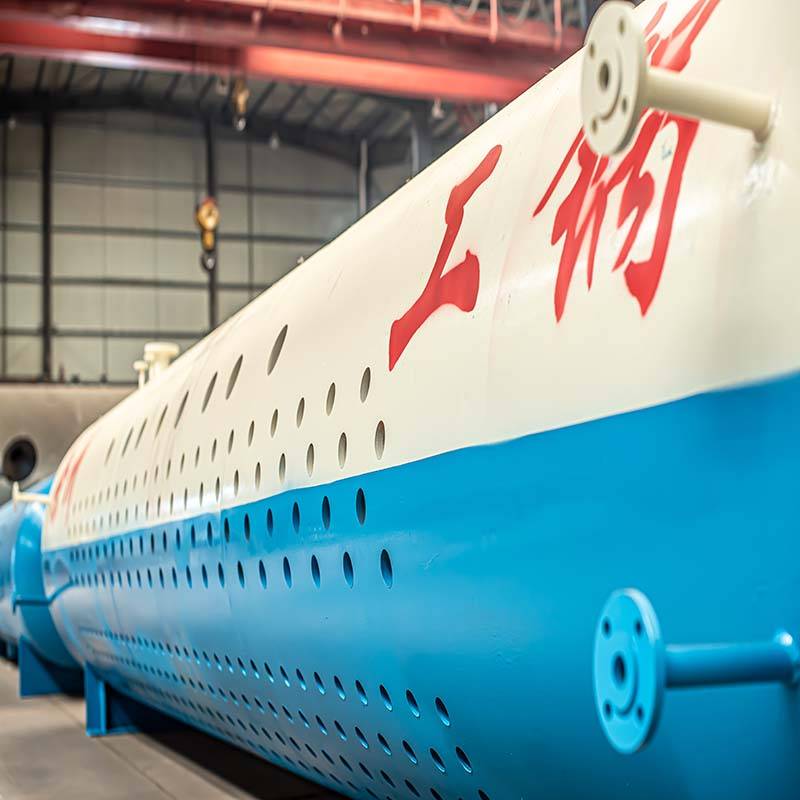

I.D fan used in Coal Boiler

boiler induced draft fan is designed for the industrial boiler (1-20T / h) or domestic boiler equipped with various coal quality and smoke and dust removal device. It can be selected for the same air inlet conditions and performance, but the high temperature is ≤ 250 ℃. Before induced draft, a dust removal device with efficiency ≤ 85% must be installed to ensure that the dust content of flue gas entering the fan is 400mg/m3

Product detail pictures:

Related Product Guide:

Boiler Structure

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for Fire Tube Boiler Supplier - Coal Boiler Biomass Boiler I.D.Fan – Double Rings , The product will supply to all over the world, such as: Chicago, Mexico, Kyrgyzstan, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad!

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

Write your message here and send it to us