Manufacturer of Boiler Wood - Boiler Sample Cooling Collection – Double Rings

Manufacturer of Boiler Wood - Boiler Sample Cooling Collection – Double Rings Detail:

Used in Boiler

Sampling Cooler

This entry was reviewed by the “Popular Science China” science encyclopedia entry compilation and application project.

An instrument used for sampling and cooling of soda-water samples in a boiler room or power plant.

The sampling cooler comprises a cooling water tank, an inlet pipe, a flange cover, a outlet pipe, a busbar and a plurality of cooling coils;

It can effectively improve the accuracy of water quality analysis, and at the same time the connecting point between the equipment is simple.

Structure

Connected with flange cover the top of the cooling water tank is equipped with coil pipe mouth of the flange cover with holes, in the middle of the cooling coil set in cooling water in the box, the outlet and inlet end of the cooling coil respectively through Kong Yanshen to cooling water tank, among them, the entry of the cooling coil and connected to the boiler, the export of cooling coil, directly above the bus slot of the water in the cooling coil by cooling coil exports into confluence worse, bus slot connected at the bottom of the drain;

The bottom of the cooling water tank is provided with a water inlet, the outlet of the water inlet pipe is connected with the water inlet of the cooling water tank;

The top of the cooling water tank is also provided with an outlet, and the inlet of the outlet pipe is connected with the outlet of the cooling water tank .

Principle

Sampling cooler used for boiler room or soda assay sample cooling power station, the water in the boiler and heating system mostly higher temperature, and high temperature is not convenient to sampling, also not easy to determine, in the sample should be cool, so let’s introduce the sample of sampling point sampling cooler for cooling, general requirements to ensure traffic in the 500-700 ml/min, the sample can take a 30 to 40 degrees cold, satisfy the People’s Republic of China power industry DL/T 457-91 standard.

Characteristics

The sampling cooler is suitable for sampling medium such as liquid and gas with high temperature. It has the advantages of compact structure, high heat transfer efficiency, convenient cleaning and long service life.

Specifications

1: The sampler tube is stainless steel and the housing is carbon steel.

2. Generally, the sampling cooling pipe can be welded and flange with diameter of 10, 12, 14, 16 and 18mm (or optionally specified by the user). The cooling water interface is DN25 with external thread.

3: The general types are qYl-159/0.32, QYl-219/0.40 and QYl-273/0.54.

4: Whether to combine (that is, whether to support, water tank, valve, etc..

Sampling procedure

1.Boiler water sampling

The boiler water sample is generally taken out of the continuous drain pipe of the drum and sent to the cooler.

The sampling point should be as close as possible to the outlet of the drain line drain drum and as far as possible before the first drain valve behind the drain drum.2.Sampling of feed water

The sampling point of the water supply is generally set after the feed pump, and a small pipe should be connected to the vertical pipe line of the water supply pipe on the high-pressure feed pipe before the economizer, from which the sample of the water supply is led to the sampling cooler.

The sampling tube of the feed water should be located at a place where the feed water can be mixed after dosing.

3.Sampling of condensed water

The condensate water sampling point is generally located in the condensate water pipe at the outlet of the condensate pump, should not be installed in the condensate pump entrance, because the pressure of the condensate pump entrance is lower than atmospheric pressure.

4.Hydrophobic sampling

The drainage is generally sampled in the drainage tank.

The sampling point is usually located about 300mm away from the bottom of the drain tank.

Steam samples are condensed into water through the sampling cooler.

The steam flow rate in the steam sampler is generally 20-30kg/h.

The requirements for the sample lead – out duct and cooler are the same as for water sampling.by metal corrosion products in the tubes during sampling.

Attention

Stainless steel tubes shall be used for sampling. Carbon steel tubes or brass tubes shall not be used to avoid contamination of the samples by metal corrosion products in the tubes during sampling.

Product detail pictures:

Related Product Guide:

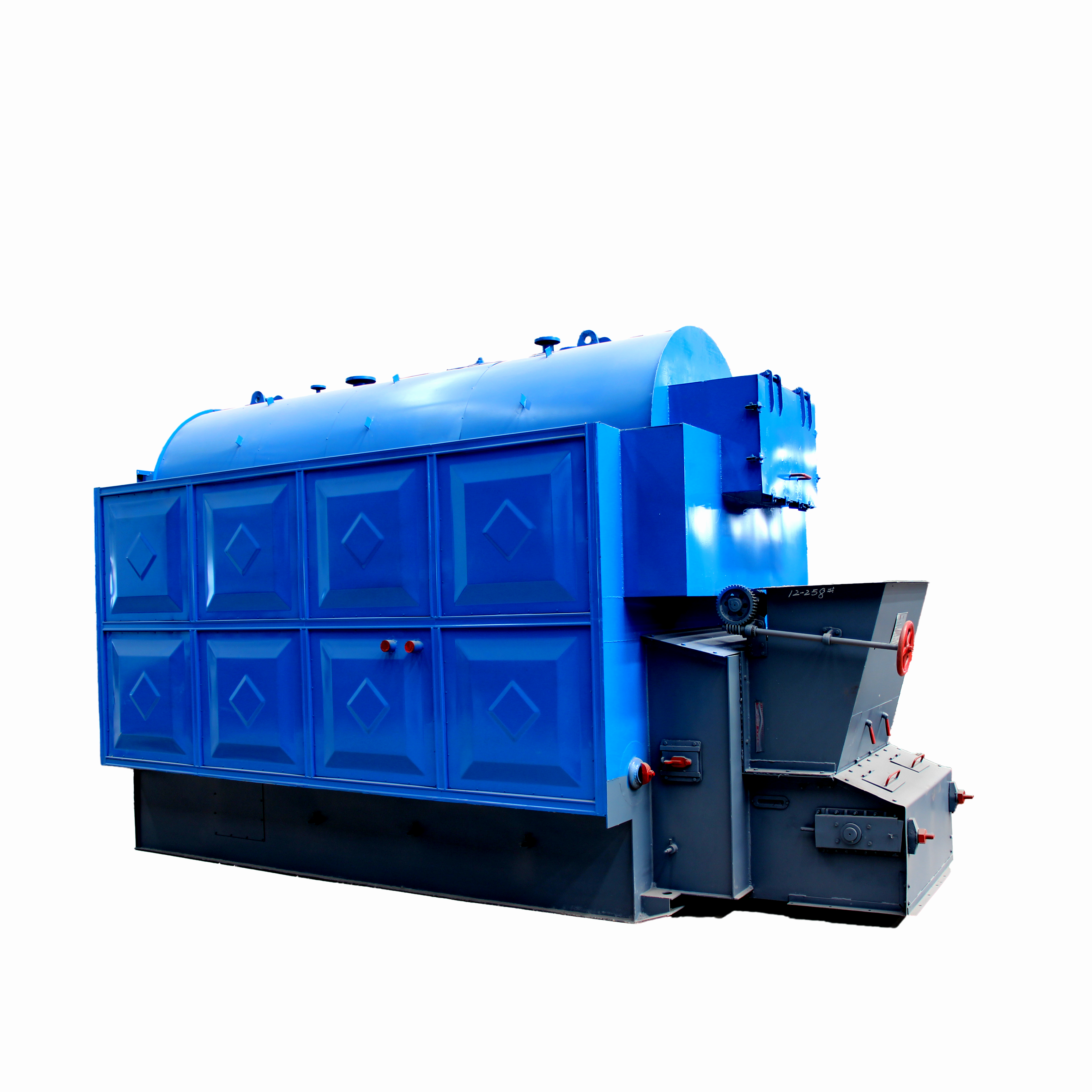

Boiler Structure

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Manufacturer of Boiler Wood - Boiler Sample Cooling Collection – Double Rings , The product will supply to all over the world, such as: Las Vegas, Portugal, Morocco, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!