Manufacturing Companies for Biomass Boiler - Biomass Hot Water Boiler – Double Rings

Manufacturing Companies for Biomass Boiler - Biomass Hot Water Boiler – Double Rings Detail:

Introduction :

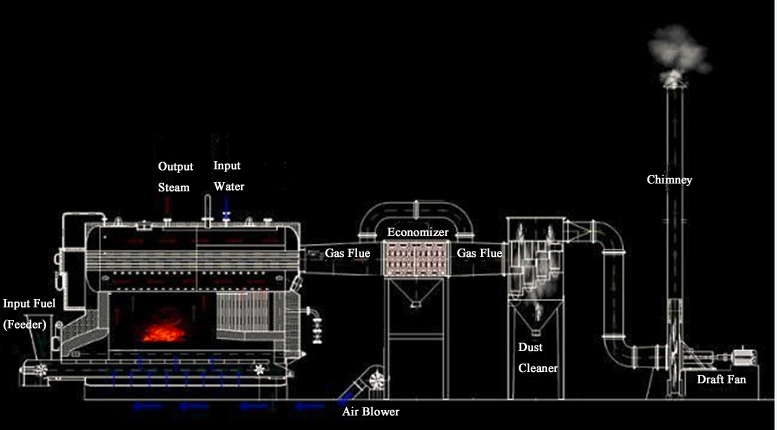

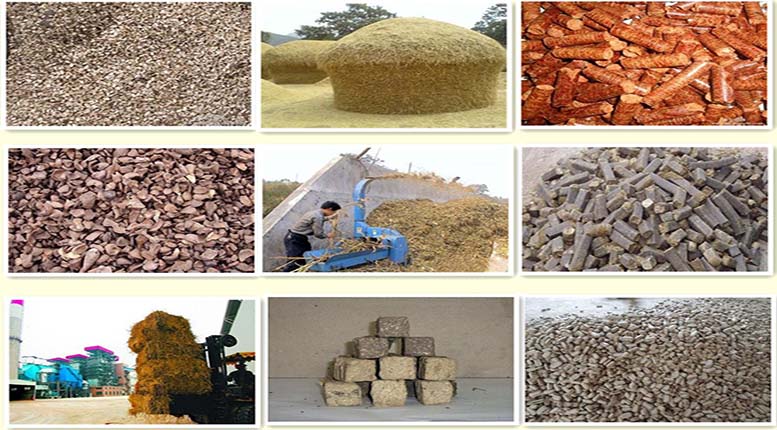

Biomass boiler is horizontal three-back water fire pipe composite boiler. The fuel can be Biomass,coal,wood,rice husk,shells,pellets,bagasse,waste etc..

Display

Feature:

1. High thermal efficiency

2. By mechanize operation, reduce intensity of labour of stoker.

3. Easy for installation, when on site, only install slag remover, valve, pipe, water and power, etc., the boiler can be launched into running, additionally, the firing is fast.

4. Easy for installation and moving, save a great amount of capital outlay.

5. Fule: Biomass, coal, wood, rice husk, shells, pellets, bagasse, waste , lower calorific value: 12792KJ/Kg.

Parameter :

DZG(L)Bearing Pressure Hot water boiler

Main Technology Parameter List

| Model | DZG0.7-0.7/95/70 DZL0.7-0.7/95/70 |

DZG1.4-0.7/95/70 DZL1.4-0.7/95/70 DZL1.4-1.0/115/70 |

DZL28-1.0/115/70 DZL2.8-1.25/130/70 |

DZL4.2-1.0/115/70 DZL4.2-1.25/130/70 |

|

| Rated Capacity T/h | 0.7 | 1.4 | 2.8 | 4.2 | |

| Rated Working Pressure Mpa | 0.7 | 0.7/1.0 | 1.0/1.25 | 1.0/1.25 | |

| Rated Steam Temp. ℃ | 95 | 95/115 | 115/130 | 115/130 | |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | |

| Fuel Consumption Kg/H | ~150 | ~310 | ~590 | ~900 | |

| Thermal Efficiency % | 75 | 78 | 79 | 77.44 | |

| Heating Surface | Boiler Body m² | 32.4 | 33.85 | 75.75 | 142 |

| Economizer m² | 24.64 | 38.5 | 87.2 | ||

| Grate area m² | 1.4/2.05 | 2.3/3.5 | 4.66 | 7.4 | |

| Designed Fuel Type | Biomass | Biomass | Biomass | Biomass | |

| Max. Transport Weight T | ~16 | ~21 | ~26.5 | ~30 | |

| Max. Transport Dimension m | 4.3×2.25×2.955.26×2.25×2.95 | 5.1×2.2×3.35.9×2.2×3.3 | 6.5×2.6×3.5 | 6.01×3.4×3.57.29×2.9×1.7 | |

| Model | DZL7-1.0/115/70 | DZL14-1.0/115/70 | DZL29-1.25/130/70 | DZL46-1.25/130/70 | DZL58-1.25/130/70 | DZL70-1.25/130/70 |

| Rated Capacity T/h | 7 | 14 | 29 | 46 | 58 | 70 |

| Rated Working Pressure Mpa | 1.0 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| Rated Steam Temp. ℃ | 115 | 115 | 130 | 130 | 130 | 130 |

| Feed Water Temp. ℃ | 70 | 70 | 70 | 70 | 70 | 70 |

| Heating AreaBoiler Body m² | 228.6 | 434.7 | Radiation:73.07Convection:903.01 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 | Radiation:147.8Convection:1418.5 |

| Grate area m² | 11.5 | 22.5 | 34.5 | 57.8 | 77 | 91 |

| Fuel Consumption Kg/h | ~1440 | ~2700 | ~6610 | ~10500 | ~12800 | ~15300 |

| Thermal Efficiency % | 80 | 80 | 82.5 | 82.05 | 83.03 | 83.28 |

| Max. Transport Weight Ton | 35 | 28 | 19.68 | 28.796 | 31 | 31 |

Note: Parameter is just for reference, the exact parameter should follow the factory technical data.

Product detail pictures:

Related Product Guide:

Boiler Structure

We can always satisfy our respected customers with our good quality, good price and good service due to we are more professional and more hard-working and do it in cost-effective way for Manufacturing Companies for Biomass Boiler - Biomass Hot Water Boiler – Double Rings , The product will supply to all over the world, such as: Sacramento, Paris, Afghanistan, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.