structure

overall

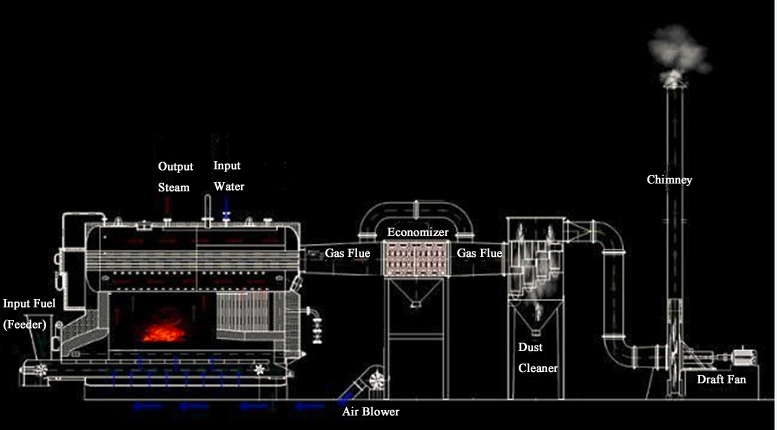

The overall structure of the boiler includes two parts: the boiler body (drum), auxiliary equipment and safety devices. The main components of the boiler, such as the hearth, drum, burner, water wall, superheater, economizer, air preheater, frame and furnace wall, constitute the core part of steam production, which is called the boiler body. The two most important parts in the boiler body are the furnace and the drum.

The furnace, also called the combustion chamber, is the space for fuel combustion. The furnace where solid fuel is placed on the grate and burned in the fire-bed is called a stratified furnace, also known as a fire-bed furnace; the furnace where liquid, gas or solid fuel ground into powder is sprayed into the fire chamber for combustion is called the chamber Burning furnace, also known as fire chamber furnace; air lifts coal particles to make them burn in boiling state, and is suitable for burning inferior fuels. The furnace is called fluidized bed furnace, also known as fluidized bed furnace. The air flow makes coal particles rotate at a high speed. Cylindrical furnace with intense fire is called cyclone furnace. Auxiliary equipment and safety devices include safety valves, pressure gauges, water level gauges, water level alarms, fusible plugs, etc.

Furnace design

Furnace design needs to fully consider the characteristics of the fuel used. Each boiler should try to burn the fuel originally designed. The economy and reliability of boiler operation may be reduced when fuels with large differences in burning characteristics are used.

It is a cylindrical container that receives feed water from the economizer, connects the circulation loop, and delivers saturated steam to the superheater in natural circulation and multiple forced circulation boilers. The boiler drum is made of high-quality thick steel plate and is one of the most important parts of the boiler.

Main functions of the drum

The main function of the drum is to store water, separate the steam and water, remove the salt water and sludge in the boiler water during operation, and avoid the boiler water with high concentration of salt and impurities from entering the superheater and steam turbine with the steam.

Inside the drum

Including steam-water separation and steam cleaning devices, water distribution pipes, sewage and dosing equipment, etc. The function of the steam-water separator is to separate the saturated steam and moisture from the water wall, and to minimize the small water droplets carried in the steam. Baffles and gap baffles are commonly used in medium and low pressure boilers as coarse separation elements; in addition to the extensive use of various types of cyclones for coarse separation in boilers above medium pressure, they also use shutters, steel wire mesh or steam equalizing plates for further separation. . The drum is also equipped with water level gauges, safety valves and other monitoring and protection facilities.

Post time: Sep-22-2020