OEM Factory for Lpg Steam Boiler - Coke Boiler – Double Rings

OEM Factory for Lpg Steam Boiler - Coke Boiler – Double Rings Detail:

Instruction

DZH Coking coal Boiler adopts high efficient heat transfer components – threaded pipe, with a reasonable flue flow rate, boiler efficiency is higher than the national professional standards 6~8%; the convex tube plate and threaded pipe make the boiler drum from quasi-rigid body to quasi-elastic body, which be with airfoil style flue completely avoid the drawbacks of traditional fire tube boiler high temperature tube plate cracking. The boiler dust inertia separation combined with efficient water film dust collector make the ash to meet the requirements of Class A.

The series coking boiler can reach the environmental effects of the gas boiler by burning bituminous coal cost , environmental protection and energy saving.

Parameter :

DZH Coking coil boiler

Main Technology Parameter List

| Model | DZH1-0.7-T | DZH2-1.25 | DZH4-1.25-T | DZH6-1.25-T | DZH8-1.25-T | DZH10-1.25-T | ||

| Rated Capacity | 1 T/h | 2 T/h | 4 T/h | 6 T/h | 8 T/h | 10 T/h | ||

| Rated Working Pressure | 0.7 Mpa | 1.25 Mpa | 1.25 Mpa | 1.25 Mpa | 1.25 Mpa | 1.25 Mpa | ||

| Rated Steam Temp. ℃ | 171 | 194 | 194 | 194 | 194 | 194 | ||

| Feed Water Temp. ℃ | 20 | |||||||

| Heating Surface | Boiler Body m² | 25.27 | 33.85 | 76 | 142 | 160 | 207 | |

| Economizer m² | 17.7 | 35.4 | 59 | 87.2 | 122.08 | 140 | ||

| Grate area m² | 1.97 | 2.68 | 3.97 | 6.9 | 7.4 | 9.2 | ||

| Design Fule | Metallurgical coke ,foundry coke I II | |||||||

| Fuel Consumption Kg/H | ~120 | ~230 | ~475 | ~665 | ||||

| Thermal Efficiency % | 76 | 78 | 78 | 78 | 79 | 80 | ||

| Max. Transport Weight | ~9 T | ~14.5T | ~21T | ~25T | ~30T | ~20T | ||

| Max. Transport Dimension | 3.95×1.9×2.6 | 4.2×2.7×3.0 | 5.8×2.8×3.2 | 6.57×2.75×3.45 | 7.1×3.2×3.5 | 7.6×3.2×3.5 | ||

| Finished boiler size m | 3.95×1.9×2.68 | 4.2×2.9×4.2 | 5.8×3.5×4.4 | 6.6x3x3.6 | 7.2x4x4.2 | 7.7×4.1×4.5 | ||

| Boiler Auxiliary Equipment Model and Specification | ||||||||

| Air Blower | Model | Y6-30-12Left 90° | YX-9-35Left 90° | YX9-35Right 0° | GY6-1Right 0° | 10TYRight 0° | 10TYRight 0° | |

| Motor Power | N=4 Kw | N=7.5 Kw | N=18.5 Kw | N=30 Kw | N=45 Kw | N=45 Kw | ||

| Draft Fan | Model | T4-72 Right 0° | T4-72 Right 315° | T4-72 Right 315° | GG6-1Right 225° | 10TGRight 225° | 10TGRight 225° | |

| Motor Power | N=1.1 Kw | N=2.2 Kw | N=5.5 Kw | N=7.5 Kw | N=14 Kw | N=15 Kw | ||

| Feed Water Pump | Model | W vortex | 1½ GC5x7 | 1½ GC5x7 | DG6-25×6 | DG12-25×6 | DG12-25×7 | |

| Motor Power | N=3 Kw | N=7.5 Kw | N=7.5 Kw | N=7.5 Kw | N=11 Kw | N=15 Kw | ||

| Dust Remover | Water Film Dust Remover | |||||||

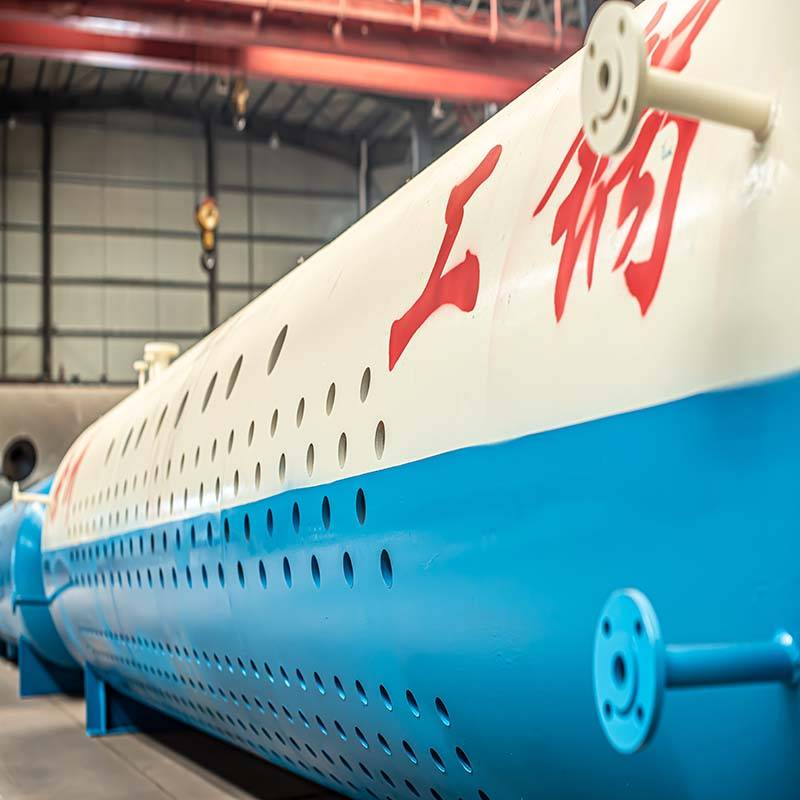

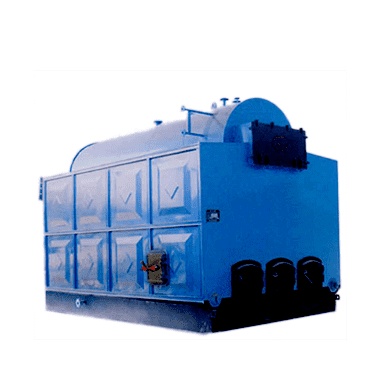

Product detail pictures:

Related Product Guide:

Boiler Structure

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for OEM Factory for Lpg Steam Boiler - Coke Boiler – Double Rings , The product will supply to all over the world, such as: Czech Republic, Brunei, Boston, For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!