OEM/ODM Factory Natural Gas Steam Boiler - Biomass Steam Boiler – Double Rings

OEM/ODM Factory Natural Gas Steam Boiler - Biomass Steam Boiler – Double Rings Detail:

Biomass Boiler-Hot Sale- Easy Installation Low Heating Value Fuel Wood Rice Husk Pellets etc.

Introduction :

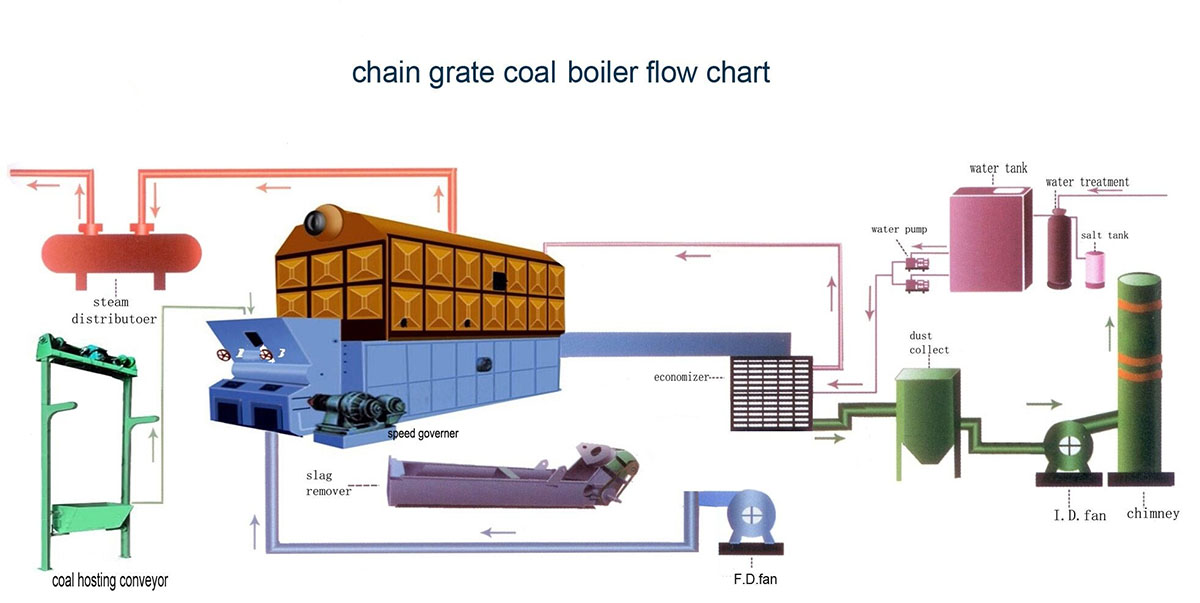

Biomass Steam Boiler is horizontal three-back water fire pipe composite boiler. Fix fire tube in drum and the light pipe water wall is fixed on the right and left sides of the furnace. With light chain grate stoker for mechanical feeding and by the draft fan and blower for mechanical ventilation, realize mechanical taphole by scraper slag remover.

The hopper of fuel drops to grate bar, then enter furnace for burning, by the ashes room above the back arch, the flame gets through the first backhaul fire tube to front smokebox, then turn back from front smokebox to the second flue for economizer and dust collector, at last, released into the atmosphere by the draft fan through chimney.

Display

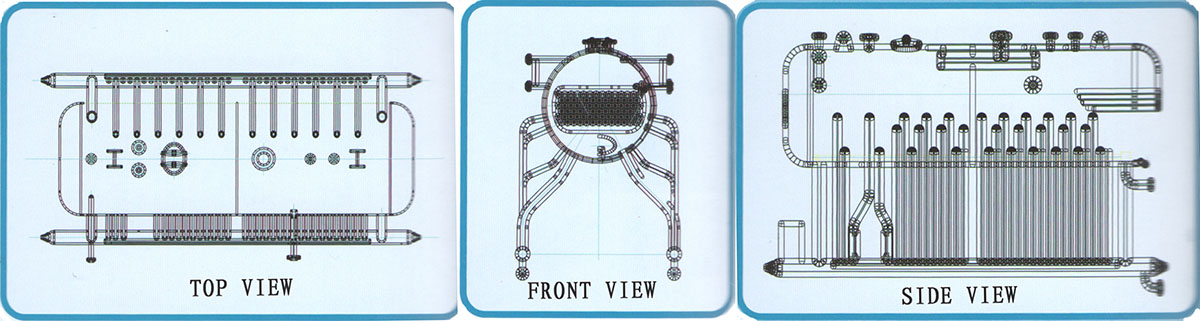

Structure

Biomass Boiler Feature:

1. High thermal efficiency

2. By mechanize operation, reduce intensity of labour of stoker.

3. Easy for installation, when on site, only install slag remover, valve, pipe, water and power, etc., the boiler can be launched into running, additionally, the firing is fast.

4. Easy for installation and moving, save a great amount of capital outlay.

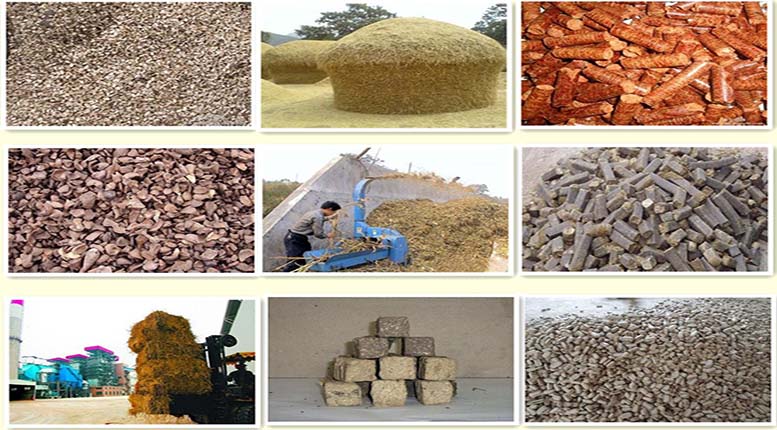

5. Fule: Biomass, coal, wood, rice husk, shells, pellets, bagasse, waste , lower calorific value: 12792KJ/Kg.

Parameter :

DZG(L)Horizontal Type Biomass-Burning Steam Boiler

Main Technology Parameter List

| Model | DZG2-1.0-S DZL2-1.25-S DZL2-1.57-S DZL2-2.45-S |

DZG4-1.25-S DZL4-1.25-S DZL4-1.57-S DZL4-2.45-S |

DZL6-1.25-S DZL6-1.57-S DZL6-2.45-S |

DZL8-1.25-S DZL8-1.57-S DZL8-2.45-S |

DZL10-1.25-S DZL10-1.57-S DZL10-2.45-S |

|

| Rated Capacity T/h | 2 | 4 | 6 | 8 | 10 | |

| Rated Working Pressure Mpa | 1.0/1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | 1.25/1.57/2.45 | |

| Rated Steam Temp. ℃ | 183/194/204/226 | 194/204/226 | 194/204/226 | 203.04 | 194/204/226 | |

| Feed Water Temp. ℃ | 20 | 20 | 20/60 | 20 | 20/60 | |

| Fuel Consumption Kg/H | ~310 | ~590 | ~900 | ~1200 | ~1440 | |

| Thermal Efficiency % | 78 | 80 | 77.44 | 78 | 80.6 | |

| Heating Surface m² | Boiler Body | 33.85 | 75.75 | 142 | 205 | 347 |

| Economizer | 24.64 | 38.5 | 87.2 | 139.52 | ||

| Grate area m² | 3.5 | 4.66 | 7.4 | 8.4 | 10.98 | |

| Designed Fuel | Biomass | Biomass | Biomass | Biomass | Biomass | |

| Max.Transport Weight Ton | 21 | 26.5 | 38 | 33 | 28/29 | |

| Max. Transport Dimension m | 5.9×2.2×3.3 | 6.5×2.6×3.524 | 7.4×3.2×4.2 | 8.1×3.2×4.2 | 7.6×3.2×3.5 | |

Product detail pictures:

Related Product Guide:

Boiler Structure

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of OEM/ODM Factory Natural Gas Steam Boiler - Biomass Steam Boiler – Double Rings , The product will supply to all over the world, such as: Austria, Singapore, Peru, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!