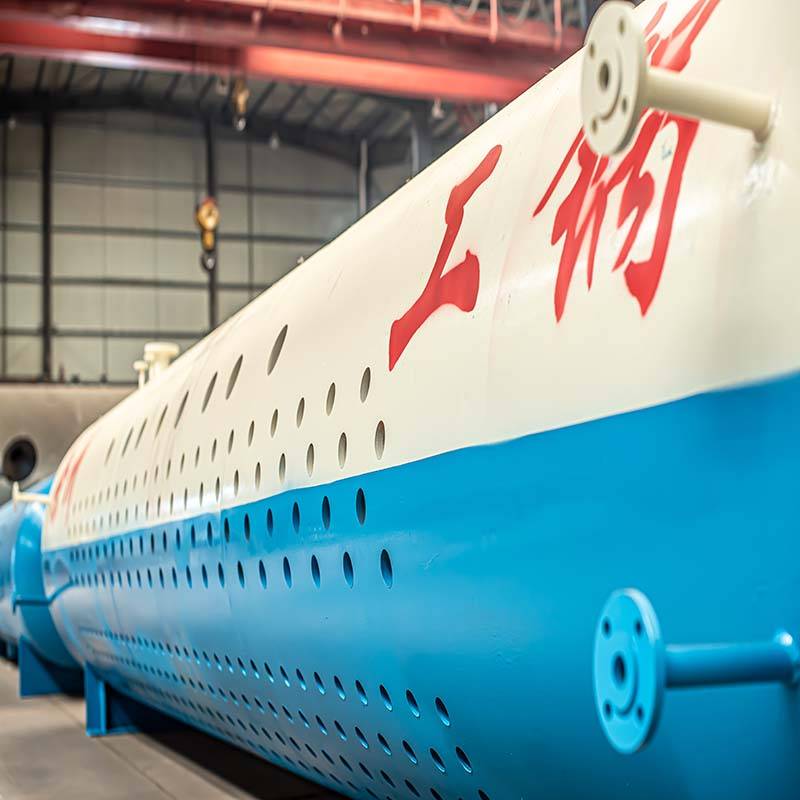

Rapid Delivery for Condensing Gas Boilers - LPG Pressure Tank – Double Rings

Rapid Delivery for Condensing Gas Boilers - LPG Pressure Tank – Double Rings Detail:

Introduction:

Pressure vessel equipment plays an important role in the petrochemical industry, the energy industry, scientific research and military sectors etc.

Pressure vessel container body consist of cylinder, sealing head, flange, sealing elements, open pore and connected pipe, bearing.

In addition, also equipped with safety devices, meter and safety internals for protection purpose .

Pressure Vessel Main Performance Parameter List

Steam Pressure1.0Mpa

Inlet Temperature 250℃

Saturation Temperature 179℃

Heating Water:Inlet Temperature 90℃;

Outlet Temperature 140℃

Product detail pictures:

Related Product Guide:

Boiler Structure

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Rapid Delivery for Condensing Gas Boilers - LPG Pressure Tank – Double Rings , The product will supply to all over the world, such as: Brasilia, Miami, Mozambique, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Write your message here and send it to us