Short Lead Time for Biomass Boiler Cost - Boiler Water Treatment – Double Rings

Short Lead Time for Biomass Boiler Cost - Boiler Water Treatment – Double Rings Detail:

More photos

1. Quartz sand filter — mainly used for the removal of sediment from water.

2. Active Carbon filter– mainly used for chlorine removal and other organic gases and to clear up the taste of water .

3. Water Softener– exchange “ions” of calcium and magnesium with the most common and easiest method.

4. Precision filter– mainly used for removing microorganisms,chlorine,part of the heavy metal ions more precisely

5. High pressure pump– Provide the high pressure to RO membrane ro.

6. RO system– main part of the plant. The RO membrane’s desalting rate can reach 99%, removing over 99% ions.

RO membranes combine auto wash and manual wash together which can protect RO membrane easily.

7. Ozone generator – Kills 99.9 percent of known harmful bacteria.

Product detail pictures:

Related Product Guide:

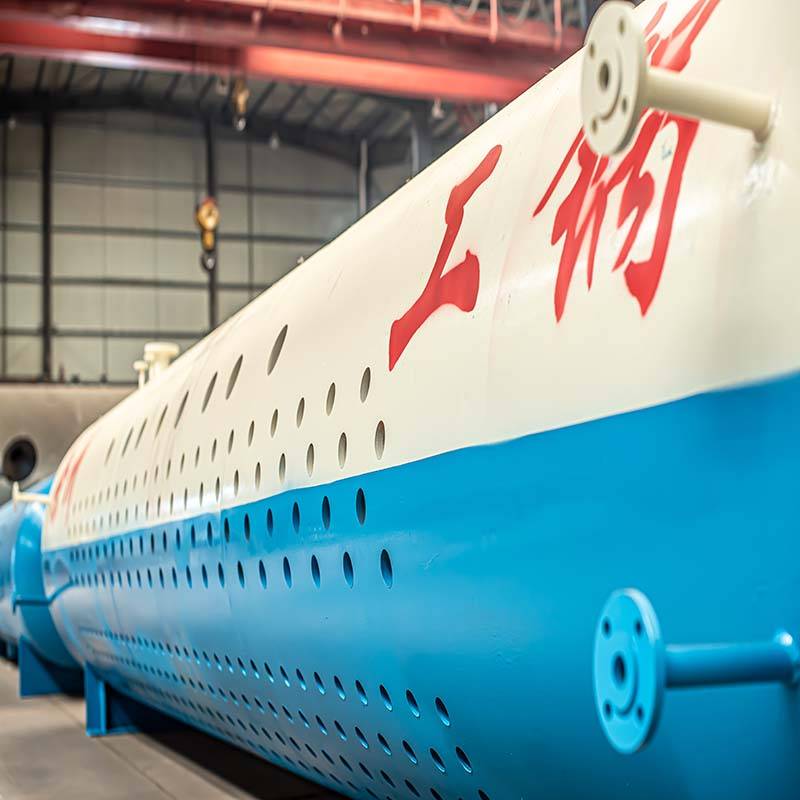

Boiler Structure

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Short Lead Time for Biomass Boiler Cost - Boiler Water Treatment – Double Rings , The product will supply to all over the world, such as: kazakhstan, Juventus, Morocco, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.